Benefits of PaperFoam®

Choosing PaperFoam® packaging means embracing sustainability while enjoying these unique advantages:

Take the step toward biobased packaging today! Contact our headquarters in Europe, Asia, or the United States by phone, or click the ‘Get in touch’ button to request a sample or explore partnership opportunities.

Making PaperFoam®

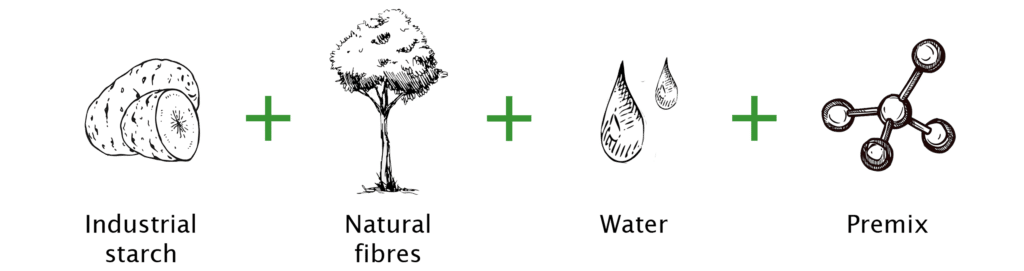

Step 1: make biobased packaging mix

You decide the design, color, and style of your PaperFoam® packaging. Our biodegradable packaging is highly versatile and can be molded into virtually any shape using injection molding. By combining four natural ingredients, we create a thick paste that is carefully injected into custom molds to bring your vision to life.

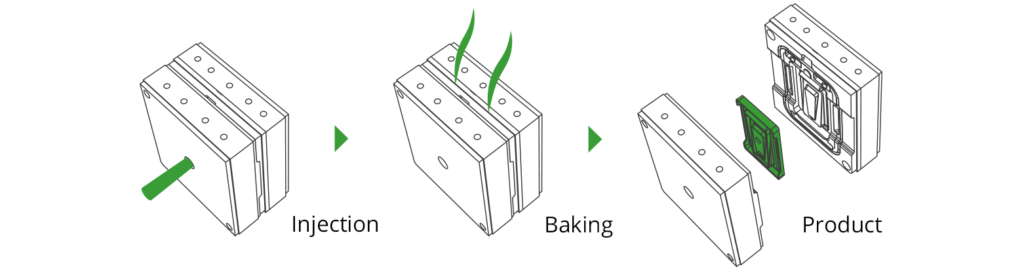

Step 2: form biobased packaging

The mixed material is injected into durable aluminum molds and baked at approximately 400 °F (204 °C). Once the mold opens, the PaperFoam® part is carefully ejected. Each piece undergoes a thorough quality check before being stacked and shipped, delivering your new biobased packaging right to your doorstep.

Weight reduction and protection

PaperFoam® packaging is up to 40% lighter than traditional packaging, offering significant weight reduction without compromising protection. In fact, its lightweight design provides superior cushioning, ensuring your product is even better protected compared to conventional packaging.

Discover more about our commitment to sustainability!

Customized packaging

Because we create the PaperFoam® mixture from scratch, any color can be added to suit your needs. Additionally, all molds are fully customized to your specifications. Whether you need extra texture, stackable trays, or your logo integrated into the biobased packaging, we’ve got you covered. With PaperFoam®, everything is 100% customizable.

Curious as to what previous biobased packaging we created? See some of the packaging solutions in our portfolio.

Contact PaperFoam®

Make a positive impact on the planet and give back to nature by choosing PaperFoam® as your new biobased packaging solution. Get in touch with our headquarters in Europe, Asia, or the United States today by dialing +31 (0) 342 401 667.

Click the ‘Get in touch’ button to receive a sample of PaperFoam® packaging.